Biodegradable paper yogurt spoon cake knife paper products spoon fork knife cutlery making machine p

| Price | $150.00/Piece |

| Min quantity | 1Piece |

| Quantity | 999Piece |

| Deliver | In 7 days |

Overview

Essential details

Applicable Industries:

Hotels, Food & Beverage Factory, Restaurant, Home Use, Food Shop, Food & Beverage Shops, Other

Showroom Location:

None

Condition:

New

Product Type:

Other

Processing Type:

Cutting Machine

Place of Origin:

Zhejiang, China

Brand Name:

LISHENG

Voltage:

220V/380 V

Power:

80KW

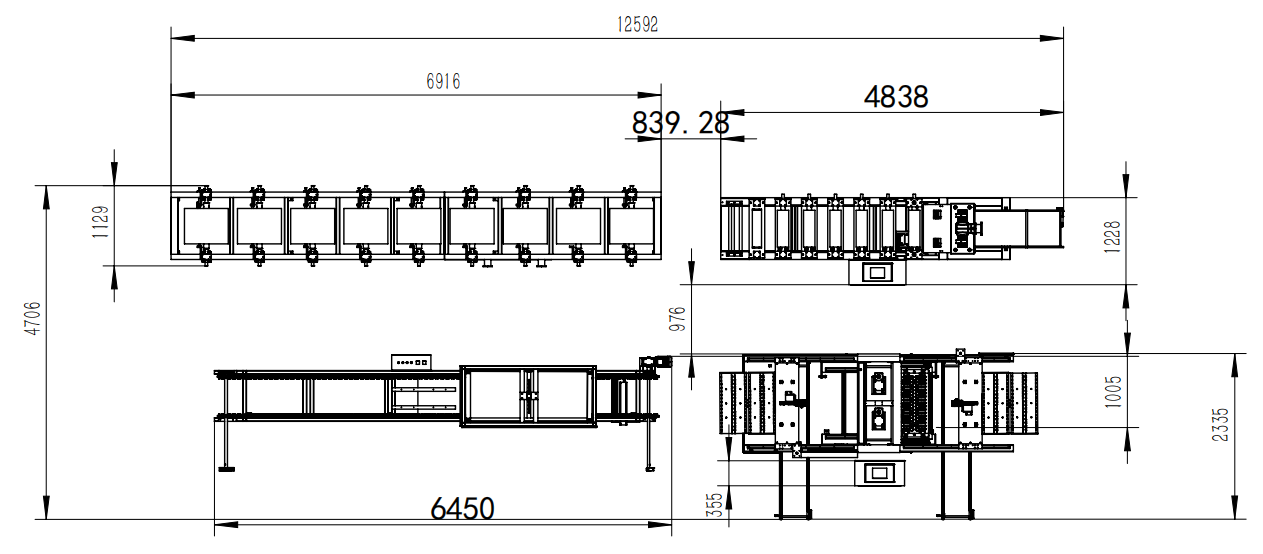

Dimension(L*W*H):

100㎡

Weight:

6000 kg, 6000 kg

Warranty:

1 Year

Production Capacity:

150 pcs/min

Machinery Test Report:

Provided

Video outgoing-inspection:

Not Available

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

Engine, Gear, Motor, Bearing, Other

Output:

170 pieces/min

Raw Material:

Environmental Paper rolls

Max Paper Layers:

3-9 layers

Material Thickness:

600-1000gsm

Total Power:

80KW

Power Supply:

380V,50HZ (220V 60HZ) (3 Phase, 4lines)

Air:

>2m³/min

Installation Area:

100㎡

Supply Ability

Supply Ability

20 Set/Sets per Month or more

Packaging & delivery

Packaging Details

Film package, printing unit with wodden box

Port

Ningbo

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 80 To be negotiated

Video Description

Product Overview

paper spoon fork knife cutlery making machine

The innovative research and development of this project is in line with national industrial policies and environmental protection policies, and represents the current structural transformation of the traditional industrial economy to a green and environmentally friendly economy. It has a distinctive emerging green that is recyclable, usable, pollution-free, noise-free, energy-saving and emission-reducing. Characteristics of the environmental protection industry. The product is made of pure natural plant renewable biological resources, and has undergone high temperature disinfection during the production process, and does not produce any waste liquid, harmful gas or waste residue. The products meet the international environmental protection and sanitation requirements, are heat-resistant, water-resistant, and oil-resistant, and are suitable for microwave oven baking and refrigerator freezing and preservation.

PRODUCT SPECIFICATIONS

FEATURES AT A GLANCE

1.Lamination &glue pre-coating & die cutting part machine:

Pre-coated the raw paper (9 layers) with environmental protection glue , then hot pressing and lamination 9 layer paper to only 1 layer paper , finally die cutting with each mould. Max speed 300pcs/min ( die cutting mould can be changed ) After die cutting, the semi-finished products will be outputed by conveyor belt and collected by manually.

2. Forming part machine:

Manually place the knife, fork and spoon into the fixed fixture (36 holes), the manipulator will move it to forming station (one upper mold, two lower molds), and move the slide to the molding machine to complete the forming. After a cycle of 15 seconds, the forming finished products are stacked on the conveyor belt by suction cups, and then collected and output. Max forming speed 170pcs/min,

3. Glue Sealing & drying part machine :

it is manually placed formed spoon /knife/fork into the fixture to complete the waterproof glue sealing process. Using rail device, the chain drives the product glue sealing, drying, collecting and packaging after output.

Our Team